Share this

How to Create and Document a Workflow Reliably and Accurately

by Jeff Ross on February 10, 2022 5:53:18 AM EST

All businesses and organizations have workflows. Even individual workers always involve at least one workflow in their day-to-day operations.

When these workflows get executed efficiently, your business is also efficient, and vice versa: inefficient workflows will result in missed deadlines, lost opportunities, and losses in revenue, profits, and even reputation.

But what are workflows, and why is it important to document your workflow? More importantly, how can we optimize these workflows to be as efficient as possible?

In this guide, we will discuss:

-

What is a workflow

-

Different types of workflow

-

Why you should document your workflow

-

How to document your workflow reliably and accurately

-

How to analyze the established workflow

-

How to optimize the workflow to make sure it’s as efficient as possible

And more!

What is a Workflow

A workflow is, simply put, a series of work that flows, hence the name.

More specifically, a workflow is a series of tasks or actions (the work) that is practiced sequentially to achieve a particular objective.

In businesses, a workflow must achieve a specific business objective, or in short, it must generate value.

As mentioned, all businesses always feature at least one workflow, and although workflows can come in many different forms and types, business workflows typically involve:

-

Processing of raw data into processed data and/or another format. For example, the transformation of an excel sheet into an annual report.

-

The transformation of raw materials into a complete product, e.g. the manufacturing of an iPhone.

-

The movement of information from one person to another or from one department to another. For example, sending a reimbursement form to the finance department.

Workflows are everywhere, but sometimes they are not as evident and identifiable. This is why visualizing the workflow in the form of a workflow diagram (or workflow model) and documenting it is crucial if you aim to improve your business’s efficiency.

A Brief History of Workflow

The concept of workflows and documenting workflows are certainly nothing new, and in fact, the idea of workflow has been around since the early 1900s.

Henry Ford (the founder of Ford) introduced the first assembly line in 1913 to make Ford cars. The assembly line allows the Ford company to build vehicles on a part-by-part basis rather than a unit-by-unit basis, which is more efficient and cost-effective.

The invention and implementation of the assembly line essentially facilitate the creation of workflows.

During the same period, Frederick Taylor, the pioneer of scientific management, introduced a time and motion study method, which essentially measures the amount of time required to complete tasks. The idea is that by using the data collected from this research, you can identify inefficiencies and bottlenecks and find ways to eliminate these inefficiencies.

Henry Gantt, the inventor of the Gantt chart (which is still heavily used today), also contributes to the study of workflows. The Gantt chart was initially developed to accurately produce a visual timeline or schedule for the manufacturing process so supervisors and managers can track the progress of tasks against milestones.

As we can see from these early days of the workflow theory, the main idea of workflow is essentially about:

-

Identifying the workflow

-

Visualizing and documenting the workflow accurately

-

Identifying inefficiencies and bottlenecks by analyzing the amount of time required to complete tasks

-

Improve the workflow by eliminating inefficiencies

The original workflow concept is developed in the context of the manufacturing sector, and especially how to make manufacturing more efficient by reducing waste and standardizing execution. However, today the workflow concept is adopted across various industries.

Three Main Types of Business Workflows

The term “workflow” or “business workflow” is often used interchangeably with “business process” or just “process.”

However, it’s crucial to understand that while workflows and processes are closely related, they are not the same thing.

In fact, “process” is just one of the three different types of workflows, and to understand the difference, here we will learn about these three different types of business workflows.

-

Process Workflows:

We call a business workflow a process if the workflow is repeatable and the tasks (and the sequences to execute the tasks) are predictable.

In a process workflow, we can clearly define:

- Which tasks need to get done

- The task/s deadline

- Which person/team is responsible for handling each task

We can say a workflow is repeatable if it will produce the same output when given the same input over and over again (at least, with minimal variations).

For example, manufacturing a car via an assembly line is a process in a car manufacturing business. The tasks/steps required to assemble a vehicle are predictable, and if the exact steps get followed, the workflow will always produce the same exact vehicle. -

Project Workflows:

A project workflow is non-repeatable, but the tasks required to finish a project are predictable. We can define which tasks need to be performed, when they should get executed (timeline) and who is responsible for handling each task.

However, the same input(s) in a project workflow will not guarantee the same output every time.

With the same vehicle manufacturing business example, designing a new car model is a project workflow. The steps needed to develop a new vehicle might be predictable, but the project's output will be different from project to project.

However, although projects aren't exactly repeatable, we may reuse parts or the complete workflow information over again in a new project. -

Case Workflows:

A case workflow is both non-repeatable and non-predictable.

We can think of a case as a problem that requires a specific solution, just like a detective when solving a “case.”

In a case workflow, the steps/tasks required are not predictable. Only after gaining more information do the tasks will reveal themselves.

Again, with the same car manufacturing business example, fixing a problem in a car product is a case. The exact steps required to fix the issue are unclear, and different cases would require other solutions (non-repeatable).

When discussing workflow and later own, documenting workflows, most often, we will focus on processes. However, some principles of modeling and optimizing a business process can still be applied to project or case workflows.

Why Document Your Workflows

While workflows are everywhere in a business, a business or organization can consist of many people with different personalities and views.

As a result, each stakeholder or team member might interpret a workflow differently. Each may have different ideas on how to execute a task or even execute the whole process. These differences in interpretations can often lead to confusion and disputes and ultimately will cause inefficiencies.

This is where the importance of documenting a standardized workflow comes in, ensuring the whole team and organization perform the workflow consistently every time.

To document the workflow, we first have to visualize the workflow in the form of a workflow diagram.

We can use various techniques and methods to visualize a workflow, but the most common and arguably the easiest way is to use a basic ANSI flowchart.

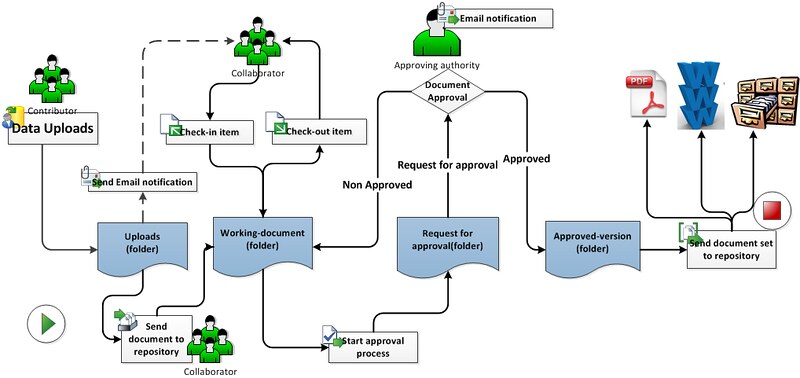

Below is an example of a simple document management workflow visualized with a basic flowchart.

As we can see, by documenting, visualizing, and structuring these workflows in a workflow diagram, we can understand:

-

The exact tasks required to fulfil the workflow

-

Who is responsible for each task

-

The time needed to accomplish each task

By understanding these three elements of the workflow, we can analyze whether the execution of the workflow is already optimal and efficient, so that we can improve upon it.

Benefits of Documenting Your Workflows

As we can see, visualizing and documenting workflows have two main functions:

-

Standardizing for Consistency:

With a properly documented and visualized workflow diagram, we’ll get a standardized roadmap on how to execute the workflow correctly.

With a properly documented and visualized workflow diagram, we’ll get a standardized roadmap on how to execute the workflow correctly.

This provides different stakeholders and team members the same vision for the workflow, eliminating disputes and confusion. We can ensure everyone is on the same page to facilitate more effective collaborations when executing the workflow.

A standardized and well-documented workflow will also facilitate easier onboarding for new hires. New employees can consult the workflow documentation and understand how the workflow is executed. -

Insights for Efficiency:

With a documented workflow diagram in place, we can get a bird’s-eye view of the whole workflow from start to finish.

With a clearer understanding of every workflow aspect, we can analyze the workflow for inefficiencies, bottlenecks, and redundancies.

A well-documented workflow map will allow us to gain more insights into how the workflow should be optimized, which will improve the efficiency of the workflow and the efficiency of the organization in general.

In turn, these two functions will provide the following benefits:

-

Improved decision-making by giving a clear overview of the entire workflow. Managers can make more data-driven, consistent, and logical decisions.

-

Eliminating bottlenecks and redundancies from workflows, allowing a more efficient workflow

-

We’ll achieve the same results while using fewer resources in a workflow execution, saving more money, time, and resources in the long run.

-

Consistent customer experience, they’ll get high-quality service/product every time.

-

A better understanding of each task and step in the workflow so we can optimize each of them.

-

Better integrations between workflows and between a workflow and technology

-

Enabling us to replace, automate, or even eliminate redundant tasks from workflows, allowing employees to use their valuable time on more critical tasks that will contribute more to achieving the organization’s goals.

Different Methods of Documenting Workflows

As mentioned, there are various ways we can use to visualize and document a workflow.

Each workflow is unique, and some methods might better visualize a specific workflow over other methods. Each workflow mapping method has a different emphasis or focus, and so a particular technique is better in understanding a particular aspect from the workflow over the other.

Here are five of the most common workflow mapping methods:

-

Insights for Efficiency:

Many of us are already familiar with the flowchart method: a visual method involving different shapes, symbols, and connectors to visualize a “flow” of process.

A flowchart effectively visualizes a sequence of tasks, inputs, and outputs of a workflow, decisions that must be made, who is involved in the workflow, and the time involved at each task. -

UML Activity Diagram

The UML (Unified Modeling Language) activity diagram is in many ways similar to the workflow method. Still, it emphasizes object-oriented mapping workflow by visualizing each task's actors, roles, artifacts, classes, and actions.

A UML allows us better to understand the activities of different actors in the workflow, so it's instrumental in helping us understand the flow of a process between various teams/departments and identifying conditions that cause particular actions or events.

-

Swimlane Diagram

Another popular method of mapping a workflow is the swimlane method, similar to the standard flowchart. The main difference is the vertical lines separating the shapes/symbols in the diagram that resemble a competitive swimming pool (hence the name “swimlane”).

These vertical lines allow us to differentiate different teams and departments involved in various tasks/steps in the workflow. So, the emphasis of this method is the interactions between teams, making this method especially useful for evaluating the efficiency of each department. -

BPMN Diagram

This method stands for Business Process Modelling Notation; this method uses different symbols that flowcharts and emphasizes the accuracy of information rather than the flows and technicalities of each task (i.e., resources required to make decisions). -

SIPOC Diagram

Stands for Suppliers-Inputs-Processes-Outputs-Customers. It can be considered an advanced swimlane diagram with five lanes (each for suppliers, inputs, processes, outputs, and customers).

SIPOC focuses on analyzing different aspects of a workflow to understand their levels of importance (rather than the sequence of tasks). Also helpful in analyzing movements of information (who creates and receives information).

How To Document Your Workflows: Step-By-Step Guide

The actual process of documenting a workflow may vary depending on the workflow itself, our purpose in documenting/analyzing the workflow, and other factors. Also, as discussed above, there are various different methods you can use:

However, you can use the following step-by-step guide to start documenting your workflow with an ANSI flowchart:

Step 1: Pick a workflow to document

While in the end, we’d want to map and document all workflows, we should start with one, so we can direct our time and resources to ensure accuracy.

If your business only has one workflow, then this step should be pretty straightforward. However, most companies have more than one workflow, so picking a workflow to prioritize can be a challenge.

In general, you can use one (or more) out of the three main approaches in deciding on which workflow(s) to prioritize)

-

Strategic approach: picking your primary business process and/or a workflow that contributes the most to your organization’s revenue

-

Reactive approach: picking a workflow with identifiable and apparent issues, for example, one that is inefficient, so you can fix this “leakage” as soon as possible

-

Customer-centric approach: picking a workflow that will directly impact user experience and/or customer satisfaction, for example, a workflow that, when optimized, will shorten the waiting time of customers

Step 2: Decide your purpose

Consider the purpose of documenting the workflow. If the sole purpose is to have a well-documented workflow, you might not need to include too many details in the workflow documentation.

If, on the other hand, the purpose of the diagram is to analyze and optimize the workflow to improve efficiency, then you’ll need to document each task more in-depth and accurately.

Based on the purpose, you can also decide who will have access to the workflow documentation. If it’s for optimization purposes, then you might not need to make it available for too many people.

If the documentation should be made available for external parties for one reason or another, then be careful not to include confidential company information in the documentation.

Step 3: Data Collecting Once you decide on a workflow and the purpose of documenting the workflow, the next step is to collect as much information as possible about the workflow.

Once you decide on a workflow and the purpose of documenting the workflow, the next step is to collect as much information as possible about the workflow.

You should collect both quantitative and qualitative data to ensure you can map the workflow accurately.

Quantitative data (complex data) is any data that can be measured in quantity, so we collect this data through observation and analyzing reports.

For example, let’s say we are going to document a car assembly workflow, then the quantitative data we can collect can include:

-

The number of cars assembled at any given time

-

The number of issues at any given time

-

The ratio between approved and rejected cars at any given time

On the other hand, qualitative data or soft data is data that cannot be measured in quantity, for example:

-

The start and end triggers of the workflow

-

What tasks are involved in each step of the business process

-

Who’s in charge of a specific task

-

The timeline of the process

-

Possible variations of the execution paths (as discussed above)

To collect qualitative information, the best approach is to interview stakeholders that are involved in the workflow. Ask as many questions as needed, and apply them in the next step of drafting the workflow documentation.

Step 4: Drafting the workflow documentation

Now that you’ve collected enough information about the workflow, you can start creating a draft of the workflow map. A workflow management solution like Approve with its workflow builder and workflow management software can help you visualize the workflow diagram, which can also help you in the documentation process.

Since you are using the ANSI flowchart method to draft the diagram, our advice is to first start with the different symbols and shapes and ignore the arrows/connectors. Once you are sure about the placements and sequence of the shapes, you can put in the arrows.

Step 5: Drafting the workflow documentation

The next step is to involve the stakeholders once again to review your draft.

Since you are documenting an as-is workflow (the documentation should represent how the workflow is currently executed and not how you hope the workflow will be), so, get feedback from stakeholders on whether the workflow is already as accurate as possible while considering:

-

The overall purpose and objectives of the workflow

-

What action triggers the start of the process, and what signals the end of the process

-

The tasks involved in each step of the process

-

Who is responsible for completing each task

-

Potential variations from this workflow

-

For any decision points, what information is needed to make a decision

Step 6: Workflow analysis and optimization

If your purpose is only to document the workflow, then congratulations, your job is finished in step 5, and you can skip step.

However, now that we’ve got a complete version of the workflow documentation, we can conduct a workflow analysis to create an improvement plan.

Analyze the workflow objectively while considering the qualitative and quantitative data you’ve collected above and identify bottlenecks and inefficiencies. Create an improvement plan on reducing or eliminating these inefficiencies and implement these changes while updating the documentation.

Once changes get implemented, we should again involve stakeholders to confirm whether the changes implemented do generate positive effects. Getting feedback from stakeholders will also help in ensuring the accuracy of the documented workflow.

Wrapping Up

Accurate documentation of your workflow will provide your business with a precise representation of a business process, which will provide a standardized roadmap for all stakeholders to ensure consistency.

An adequately documented workflow diagram would also allow us to devise workflow analysis to devise an improvement plan by identifying bottlenecks and inefficiencies and identifying ways to improve upon these issues.

Share this

- Featured (23)

- Educational (22)

- New Release (21)

- Online Proofing (20)

- Workflow Management (19)

- Project Management (18)

- Work Management (17)

- Business Workflow (16)

- Newsletter (15)

- BPM Software (10)

- Business Automation (8)

- Workflow Automation (8)

- Marketing Workflow (7)

- Digital Asset Management (6)

- Industry News (6)

- News (6)

- business process workflow (5)

- Marketing management (4)

- BPM (3)

- Marketing Automation (3)

- Task Management (3)

- AI (1)

- Aproove news (1)

- Case Studies (1)

- Case Study (1)

- DAM Software (1)

- Document Management Automation (1)

- Document Workflow Automation (1)

- Insider (1)

- enterprise project management (1)

- insurance work management (1)

- marketing process (1)

- July 2024 (8)

- June 2024 (11)

- May 2024 (6)

- April 2024 (7)

- March 2024 (7)

- February 2024 (6)

- January 2024 (4)

- December 2023 (3)

- November 2023 (7)

- October 2023 (7)

- September 2023 (3)

- August 2023 (5)

- July 2023 (3)

- June 2023 (1)

- May 2023 (1)

- April 2023 (1)

- February 2023 (2)

- September 2022 (3)

- August 2022 (1)

- July 2022 (1)

- May 2022 (1)

- March 2022 (3)

- February 2022 (3)

- January 2022 (3)

- November 2021 (2)

- October 2021 (2)

- September 2021 (1)

- August 2021 (4)

- July 2021 (4)

- June 2021 (2)

- May 2021 (3)

- April 2021 (1)

- February 2021 (1)

- November 2020 (1)

- October 2020 (2)

- July 2020 (4)

- June 2020 (2)

- May 2020 (2)

No Comments Yet

Let us know what you think